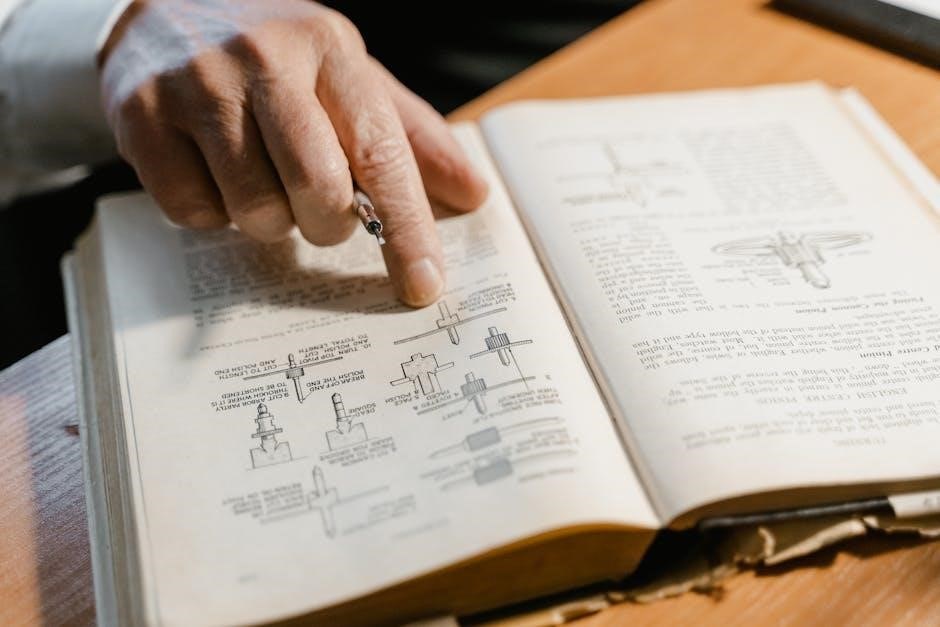

A manual transmission parts diagram provides a detailed visual guide to understanding the components and their interactions within a manual transmission system․ These diagrams are essential for identifying gears, shafts, synchronizers, and other critical parts, aiding in repairs, maintenance, and assembly․ They offer a clear overview of how each element contributes to smooth gear shifting and power delivery, making them indispensable for both professionals and DIY enthusiasts․

Overview of the Diagram

The manual transmission parts diagram offers a comprehensive visual representation of the components involved in a manual transmission system․ It provides exploded views and detailed illustrations of gears, shafts, synchronizers, and other critical parts for various transmissions, such as Dodge, GM, and Jeep T5 models․ This diagram aids in identifying components for maintenance, repairs, and assembly, making it an essential resource for professionals and DIY enthusiasts alike․ It simplifies understanding the complex interactions within the system, ensuring accurate servicing and troubleshooting․

Key Components of a Manual Transmission

A manual transmission consists of gears, shafts, clutch, synchronizers, and shift forks, each playing a crucial role in facilitating smooth gear changes and efficient power transfer․

Gears and Gear Ratios

Gears in a manual transmission are toothed wheels that mesh to transmit power․ They come in different sizes to provide varying gear ratios, which determine torque and speed․ The input shaft gears mesh with the output shaft gears, allowing the engine’s rotational force to be adjusted for various driving conditions․ Proper gear ratios ensure optimal performance, whether accelerating from a standstill or maintaining high-speed cruising․ The diagram highlights how gears are arranged and interact to achieve smooth power delivery across all gears․

Input and Output Shafts

The input shaft and output shaft are central to the manual transmission system․ The input shaft connects to the clutch and engine, transferring rotational force․ The output shaft links to the driveshaft, delivering power to the wheels․ These shafts are equipped with gears that mesh to provide varying gear ratios, optimizing torque and speed․ Bearings and seals support smooth operation, while the output shaft’s design ensures efficient power transfer․ This setup allows the transmission to adapt to different driving conditions, maintaining vehicle performance and control․

Clutch Assembly

The clutch assembly is a vital component in a manual transmission, enabling the engine to disconnect from the transmission when shifting gears․ It consists of the clutch plate, pressure plate, and release bearing․ When the driver presses the clutch pedal, the release bearing engages, separating the clutch plate from the flywheel․ This temporary disconnection allows smooth gear changes without grinding․ The clutch assembly ensures efficient power transfer and prevents wear on transmission components during shifting, making it essential for seamless vehicle operation and driver control․

Synchronizers and Hub

Synchronizers and the hub are essential for smooth gear engagement in a manual transmission․ The hub connects to the input shaft and houses the synchronizers, which ensure gears align in speed before meshing․ When shifting, the synchronizer rings engage with the gear teeth, preventing grinding and facilitating seamless transitions․ This mechanism is critical for maintaining control and reducing wear on transmission components․ The hub and synchronizers work in tandem to enable precise and efficient gear changes, making them indispensable for the overall functionality of the manual transmission system․

Shift Forks and Rods

Shift forks and rods are vital components that facilitate gear selection in a manual transmission․ The shift forks, attached to the shift rods, move along the gearbox to engage or disengage gears․ When the driver operates the gearshift, it activates the rods, which then position the forks to align with the desired gear․ This precise mechanical interaction ensures smooth transitions between gears, maintaining control and preventing misalignment․ The rods and forks work in harmony to provide accurate and efficient shifting, essential for optimal vehicle performance and driver control․

How Manual Transmissions Work

A manual transmission operates by the driver manually shifting gears using the clutch pedal and gearshift․ The clutch disengages engine power, allowing gear changes without grinding, while the gearshift selects the desired gear for optimal power delivery and mechanical efficiency․

The Gear-Shifting Process

The gear-shifting process in a manual transmission involves coordinating the clutch pedal and gearshift to change gears smoothly․ When the driver presses the clutch pedal, it disengages the engine from the transmission, allowing the gearshift to move into the desired gear․ Synchronizers ensure the gears mesh properly, preventing grinding․ As the driver releases the clutch pedal gradually, the engine reconnects with the transmission, and the selected gear engages․ Precise timing and control are essential for seamless shifting, ensuring efficient power delivery and smooth vehicle operation․

Torque Transfer and Power Delivery

Torque transfer and power delivery in a manual transmission rely on the seamless interaction between the engine, clutch, and gears․ When the clutch engages, it transfers torque from the engine’s input shaft to the transmission’s gears․ The selected gear ratio determines the speed and torque delivered to the output shaft, which powers the wheels․ This system ensures efficient energy transfer, allowing drivers to control acceleration and speed effectively․ Proper synchronization and gear engagement are critical for maintaining smooth power delivery and optimal vehicle performance․

Types of Manual Transmissions

Manual transmissions vary in design, including sliding mesh, constant mesh, sequential, and dual-clutch systems, each offering distinct operational characteristics and performance benefits for different applications․

Sliding Mesh Transmission

The sliding mesh transmission is a basic type of manual transmission where gears slide along the shafts to engage․ It operates without synchronizers, relying on the driver to match engine speed with the gear ratio․ This design is simple, lightweight, and cost-effective but requires precise driver input to avoid gear clash․ Common in older vehicles, it provides a direct mechanical connection, making it suitable for low-torque applications․ The diagram highlights key components like gears, shafts, and the lack of synchronizers, essential for understanding its functionality and maintenance․

Constant Mesh Transmission

A constant mesh transmission keeps gears in constant mesh, eliminating the need for sliding them in and out․ This design uses synchronizers to engage gears smoothly, reducing wear and tear․ It is more efficient than sliding mesh transmissions, offering better control and reduced noise․ The gears remain fixed on the shafts, and the synchronizers facilitate seamless shifting․ This system is widely used in modern vehicles due to its reliability and smoother operation, making it a preferred choice for drivers seeking improved performance and durability in manual transmissions․

Sequential Manual Transmission

A sequential manual transmission operates similarly to manual transmissions but uses a sequential gear Shift mechanism․ Instead of an H-pattern shifter, it employs a single gate, requiring the driver to shift through gears in a fixed sequence․ This setup is common in racing and high-performance vehicles, offering faster shifting and improved control․ The design eliminates the need for manual gear selection, enhancing speed and precision․ Sequential transmissions are valued for their efficiency and performance in demanding driving conditions, making them ideal for specialized applications where rapid gear changes are essential․

Dual-Clutch Transmission (DCT)

A Dual-Clutch Transmission (DCT) combines elements of manual and automatic transmissions, offering precise control and rapid shifting․ It uses two clutches to pre-select gears, enabling seamless transitions without interrupting power delivery․ This design enhances acceleration and efficiency, particularly in high-performance vehicles․ Unlike traditional manuals, DCTs automate clutch actuation but retain manual shifting capabilities․ The system is lighter and more compact, making it ideal for applications where speed and responsiveness are critical․ DCTs strike a balance between driver engagement and modern convenience, appealing to enthusiasts and everyday drivers alike․

Maintenance and Repair Tips

Regular fluid checks, timely inspections, and replacing worn parts like the clutch ensure smooth operation․ Use diagrams to identify components and address issues promptly for optimal performance․

Regular Maintenance Practices

Regular maintenance is crucial for extending the life of a manual transmission․ Key practices include checking transmission fluid levels, inspecting for leaks, and replacing the clutch when worn․ Ensure the gearshift and linkages are lubricated to prevent wear․ Referencing a parts diagram can help identify components needing attention․ Cleanliness is vital; dirt can damage gears and bearings․ Schedule periodic inspections to catch issues early, avoiding costly repairs․ Consistent upkeep ensures smooth shifting and optimal performance․

Common Issues and Troubleshooting

Common manual transmission issues include grinding gears, difficulty shifting, and fluid leaks․ Grinding gears often result from improper clutch engagement or worn synchronizers․ If gears slip or pop out, the clutch or gear bearings may be faulty․ Leaks typically stem from damaged seals or gaskets․ Using a parts diagram helps pinpoint problem areas․ Troubleshooting involves inspecting components like the input shaft, output shaft, and gear hubs․ Addressing these issues promptly prevents further damage and ensures smooth operation․ Regular inspection using a diagram can help identify and resolve problems early․

Using Diagrams for DIY Repairs

Manual transmission parts diagrams are invaluable for DIY repairs, offering a clear visual breakdown of components and their relationships․ These diagrams help identify parts like gears, shafts, and synchronizers, making it easier to understand how they interact․ By guiding through disassembly and reassembly, they reduce the risk of costly mistakes․ Diagrams also ensure correct part installation, preventing further damage․ Whether you’re a novice or experienced mechanic, a detailed diagram is essential for successful transmission repairs, providing a roadmap to properly diagnose and fix issues․

Applications and Advantages

Manual transmissions are commonly used in passenger cars, especially sports and performance vehicles, due to their fuel efficiency, lower cost, and driver control․ They offer better fuel economy, reduced maintenance, and a more engaging driving experience compared to automatics, making them a preferred choice for many drivers seeking precision and cost-effectiveness․

Vehicle Types Using Manual Transmissions

Manual transmissions are widely used in various vehicle types, including sports cars, performance vehicles, and economy-focused models․ They are also common in lightweight cars, trucks requiring driver control, and vintage or classic automobiles․ Additionally, many motorcycles and some industrial machinery utilize manual transmissions for precise power delivery and efficiency․ These systems are favored in applications where driver engagement, fuel efficiency, and lower maintenance costs are prioritized, making them a versatile choice across diverse automotive and industrial sectors․

Benefits Over Automatic Transmissions

Manual transmissions offer several advantages over automatics, including better fuel efficiency, lower production and maintenance costs, and enhanced driver control․ They typically weigh less, contributing to improved vehicle handling and performance․ Manual transmissions also provide a more engaging driving experience, allowing drivers to connect more with the vehicle․ Additionally, they are less complex mechanically, reducing the risk of costly repairs and extending the lifespan of the transmission․ These benefits make manual transmissions a preferred choice for many drivers seeking a balance of economy and performance․

Resources and Tools for Further Learning

Explore online tutorials, manufacturer manuals, and repair guides for in-depth understanding of manual transmission components․ Utilize interactive diagrams and simulation tools to enhance learning and troubleshooting skills effectively․

Online Resources and Tutorials

Various online resources and tutorials provide detailed insights into manual transmission parts diagrams, offering interactive diagrams, exploded views, and step-by-step guides․ Websites like ManualsLib and TransmissionParts․com offer free access to service manuals and exploded diagrams for popular models․ Video tutorials on platforms like YouTube and Udemy demonstrate disassembly, assembly, and troubleshooting processes․ Forums such as Reddit’s DIY community and specialized automotive forums share hands-on experiences and tips․ These resources are invaluable for learners, DIY enthusiasts, and professionals seeking to enhance their understanding of manual transmission systems․

Manufacturer Manuals and Guides

Manufacturer manuals and guides are invaluable for understanding manual transmission parts diagrams, offering detailed exploded views and part lists specific to each model․ These documents, often available on official manufacturer websites or through dealerships, provide precise specifications, torque values, and assembly procedures․ They are tailored to individual transmission types, ensuring compatibility and accuracy․ Whether for professional mechanics or enthusiasts, these guides are essential for diagnosing issues, planning repairs, and maintaining transmission systems effectively․ They often include troubleshooting tips and warranty information, enhancing their utility for users․

Essential Tools for Transmission Work

Essential tools for transmission work include a socket set, torque wrench, bearing puller, and gear installer․ A universal joint and slide hammer are also useful for dislodging stubborn parts․ Specialized tools like a countershaft locknut wrench and seal installer ensure proper installation and prevent damage․ These tools are critical for disassembling and reassembling transmission components accurately․ Using the correct tools is vital to avoid damaging intricate parts like gears and bearings, ensuring a successful repair or maintenance process․ Proper tool selection enhances efficiency and safety during transmission servicing․

A manual transmission parts diagram is a visual guide that illustrates the components of a manual transmission system․ It provides a detailed overview of gears, shafts, bearings, synchronizers, and other essential parts․ These diagrams are crucial for understanding how the transmission operates and for identifying specific components during repairs or maintenance․ They are particularly useful for professionals and DIY enthusiasts, offering a clear reference for troubleshooting and assembly․ The diagram helps in visualizing the interaction between parts, making it easier to diagnose issues and perform accurate repairs․ It serves as an indispensable resource for anyone working on manual transmissions․

The manual transmission parts diagram provides a comprehensive visual representation of the system’s components and their relationships․ It details the layout of gears, shafts, bearings, and synchronizers, offering a clear understanding of how each part interacts․ The diagram is organized to highlight the flow of power from the input shaft to the output shaft, showcasing the engagement of gears and the role of the clutch assembly․ It serves as a valuable tool for mechanics and enthusiasts, simplifying the identification of parts and aiding in troubleshooting, repairs, and assembly․ The diagram’s structured format ensures clarity and ease of use․

Key Components of a Manual Transmission

The key components include gears, shafts, bearings, synchronizers, and the clutch assembly․ These parts work together to enable smooth gear shifting and efficient power transfer․

Gears are toothed wheels that mesh together to transmit power and change speed or torque․ In a manual transmission, gears are mounted on shafts and engage in pairs to provide different gear ratios․ These ratios determine how power is delivered to the wheels, with lower ratios for more torque at lower speeds and higher ratios for higher speeds․ The arrangement of gears, including both straight-cut and helical designs, ensures smooth power transfer․ Gear ratios are critical for optimizing vehicle performance, fuel efficiency, and driving comfort across various conditions․

Manual transmissions operate by engaging gears through a clutch and shifter, using mechanical linkages to connect and disconnect power from the engine to the wheels․ Synchronizers ensure smooth gear transitions, allowing drivers to control speed and torque effectively․

The gear-shifting process in a manual transmission begins with pressing the clutch pedal, which disengages the engine from the transmission․ The driver then selects the desired gear using the shift lever, aligning the gear with the output shaft․ Synchronizers ensure smooth engagement by matching the speed of the gear to the shaft․ Once the gear is engaged, the clutch pedal is released, reconnecting the engine to the transmission․ This process requires precise timing and coordination, with diagrams often used to illustrate how gears, synchronizers, and shafts interact during shifting․

Manual transmissions come in various designs, each offering distinct advantages․ The sliding mesh transmission is the simplest, with gears engaging directly․ Constant mesh transmissions keep gears in constant contact, reducing wear․ Sequential manual transmissions (SMTs) use a single clutch and electronically controlled actuators for faster shifting․ Dual-Clutch Transmissions (DCTs) combine two clutches for seamless gear changes, blending manual control with automatic efficiency․ Each type is suited to specific applications, from racing to everyday driving, and diagrams help illustrate their unique mechanical configurations and operational differences․

valve manual

valve manual  alpine ktp 445u manual

alpine ktp 445u manual  manual toro tmc 212

manual toro tmc 212  honeywell jade controller manual

honeywell jade controller manual  manual ti 89

manual ti 89  minn kota i pilot manual

minn kota i pilot manual  amc past papers with answers pdf

amc past papers with answers pdf  tv guide monroe michigan

tv guide monroe michigan  salesforce admin certification dumps 2020 pdf free

salesforce admin certification dumps 2020 pdf free  exercise band workouts pdf

exercise band workouts pdf